The Manufacturing Execution System (MES) designed specifically for the apparel industry handles the intricacies of pre-production and production management, ensuring detailed tracking and organization of manufacturing processes. The MES for apparel focuses on the crucial cutting stage, where it offers intelligent planning and ongoing tracking of all related pre-production activities, setting the stage for seamless assembly and sewing operations.

Key Functions of MES for Apparel Manufacturing:

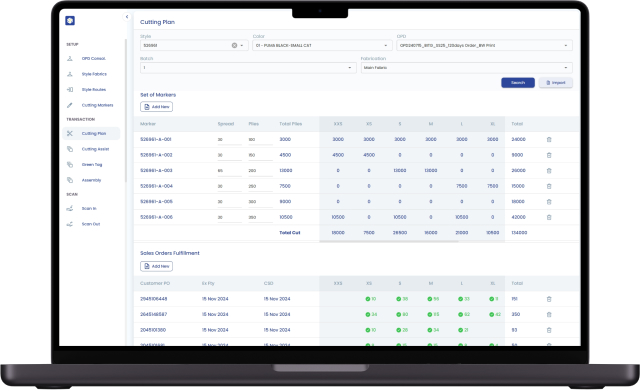

Cutting Planning

Allows for simulation of customer order fulfillment based on selected style, color, and marker set, aiding planners in managing workloads and preventing issues of over-cutting or under-cutting.

Cutting Assist

Tracks the fulfillment of orders using the actual number of fabric plies cut, with QR codes generated for each ply to facilitate easy tracking through subsequent manufacturing stages.

Assembly

Ensures accurate matching of fabric bundles to prevent color shading discrepancies, organizing complete assemblies into customer PO bundles for the sewing process.

Fabric Tracking

Monitors the completeness of all fabrications—main fabrics and sub-fabrics—to ensure a smooth flow of materials into the sewing stage.

Sewing In-Line Tracking

Captures output per sewing line at the Customer PO level, streamlining the process from assembly to sewing.

Quality Control

Implements in-line and end-line quality inspections to identify and address defects, enhancing overall product quality.

Carton Packing

Calculates requirements for carton packing and tracks the completeness of carton box closing at the Customer PO level.

Performance Analytics

Generates reports on work-in-progress (WIP) and assesses cutting and sewing efficiencies as well as pre-production subprocess efficiencies.

Main Benefits of MES

Improved Efficiency

Streamlines production schedules, reduces material wastage, and enhances the overall efficiency of production operations.

Enhanced Quality Control

Implements stringent quality checks throughout the production stages, allowing for immediate correction of defects and prevention of incomplete customer shipments.

Real-Time Data and Analytics

Offers real-time visibility into production activities, enabling proactive management of inefficiencies and quality issues.

Worker Motivation

Provides immediate feedback to workers on their performance, helping to motivate and increase productivity through incentive-based rewards.

Flexible Deployment Model

Customers have the flexibility to deploy our solution according to their preferences. They can opt for a cloud-based SaaS solution hosted by us or install the software on-premises. Our solution is compatible with both Microsoft SQL Server and MySQL databases, ensuring versatile and adaptable integration with existing IT infrastructure.

Overall, the MES for apparel manufacturing equips manufacturers with the tools needed to optimize production processes, maintain high quality standards, and improve operational efficiency, all facilitated by modern technologies like QR code tagging for cost-effective, sophisticated tracking without the need for proprietary hardware.

Let’s See How It Works for You.

Give us a call and let us do our magic!